The Difference between Hard Anodizing and Ordinary Anodizing

50% of the hard oxidized oxide film penetrates into the aluminum alloy and 50% adheres to the surface of the aluminum alloy. Therefore, the external

One-stop services manufacturer for products desgin, machining, assembly and reliable testing.

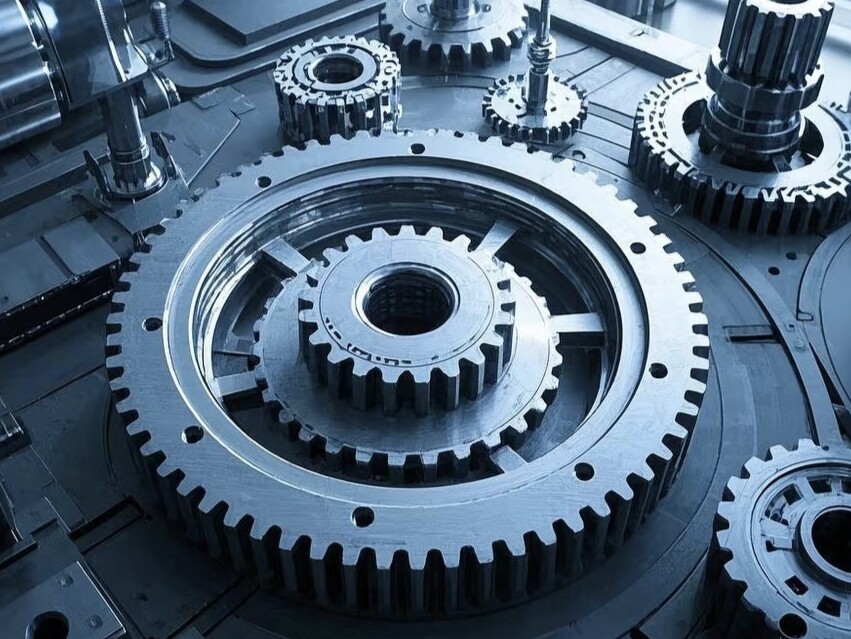

Anxin has four-axis, five-axis and other precision machining equipments. The stable processing quality and high precision products have helped us win the praise of many customers.

Our team puts the needs of our customers first and provides timely & professional solutions.

From prototype to mass production, Anxin always provides customers high quality products and fast delivery processing services.

Through the integrated processing and digital management of the machine tool, the processing accuracy of ±0.005mm or even higher can be achieved, and the consistency of large-scale products can be ensured.

5-axis CNC machining through multi-dimensional linkage cutting, compared with the traditional 3-axis machining has a more powerful processing capacity, especially suitable for high-precision, complex geometric shape parts manufacturing.

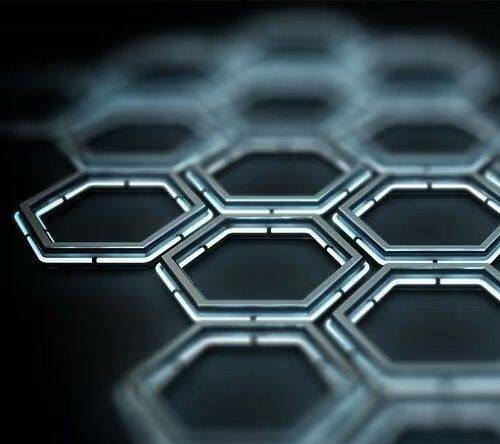

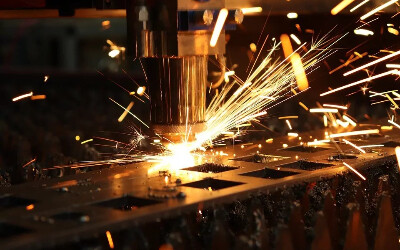

A manufacturing method of forming sheet metal through cutting, bending, stamping, welding and other processes. The cost of sheet metal processing is low, the processing is flexible and the production efficiency is high.

Please feel free to contact us for offering more customized services. Let us covey the concept of your design in works!

Get in touch with us and send us your products’ drawings for reviewing.

We will Provide a detailed quote including cost, lead time, and feasibility feedback within a few hours.

Customer approves the quote and signs a service agreement.

Payment terms (e.g., deposit, milestones) are finalized.

Raw material procurement and inspection.

Machining/processing with in-process QC checks.

Surface treatment (anodizing, plating, painting, etc.) if required.

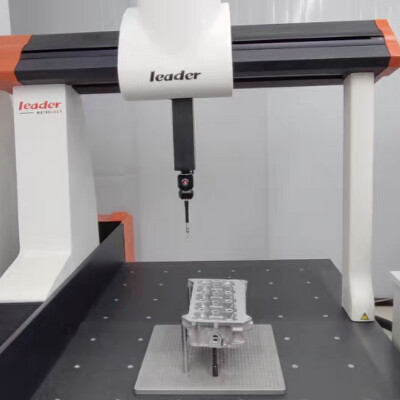

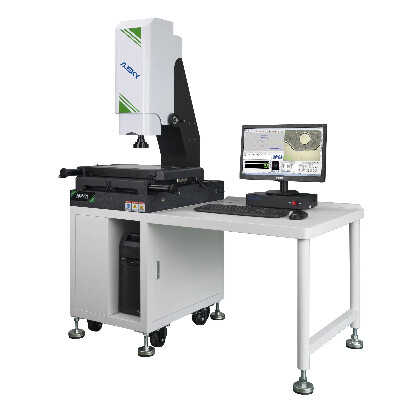

Full dimensional inspection and performance testing (e.g., CMM, hardness tests).

Share inspection reports (PDF/QC sheets) for customer approval.

Protective packaging (anti-rust, shockproof) per customer requirements.

Arrange logistics (express, sea/air freight) with tracking updates.

Warranty coverage for defects (terms outlined in the contract).

Re-machining or replacements (if applicable).

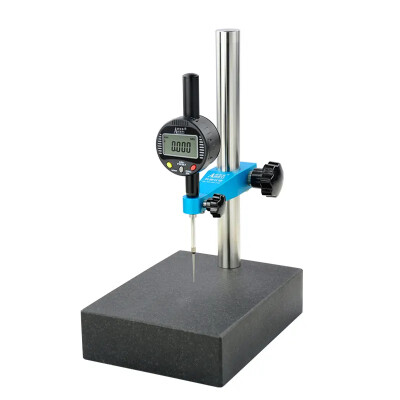

We ensure precision through advanced CNC machining processes and inspection equipments, while maintaining ISO-certified quality management systems for full traceability and consistency.

Measuring range(mm): 600*500*400

Accuracy of dense(mm): 0.001

Measuring range(mm): 200*100*200

Accuracy of dense(mm): 0.001

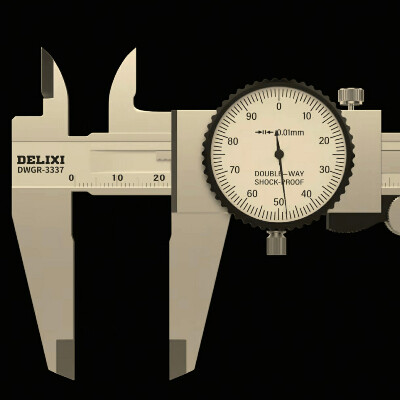

Measuring range(mm): 5-30

Accuracy of dense(mm): 0.01

Measuring range(mm): 0-300

Accuracy of dense(mm): 0.01

Measuring range(mm): 10-150

Accuracy of dense(mm): 0.001

Measuring range(mm): 0-25

Accuracy of dense(mm): 0.001

Measuring range(mm): 25-50

Accuracy of dense(mm): 0.001

Measuring range(mm): 0-58

Accuracy of dense(mm): 0.001

Measuring range(mm): NA

Accuracy of dense(mm): 0.01

Measuring range(mm): 600*500*400

Accuracy of dense(mm): 0.001

50% of the hard oxidized oxide film penetrates into the aluminum alloy and 50% adheres to the surface of the aluminum alloy. Therefore, the external

Compared with ordinary machining centers, five axis machining centers have the following significant features: 1. Suitable for processing complex and irregular parts. Five axis machining

In today’s fast-paced manufacturing landscape, computer numerically controlled (CNC) machining processes depend on maximized efficiency. Efficient CNC machining saves both time and resources while improving