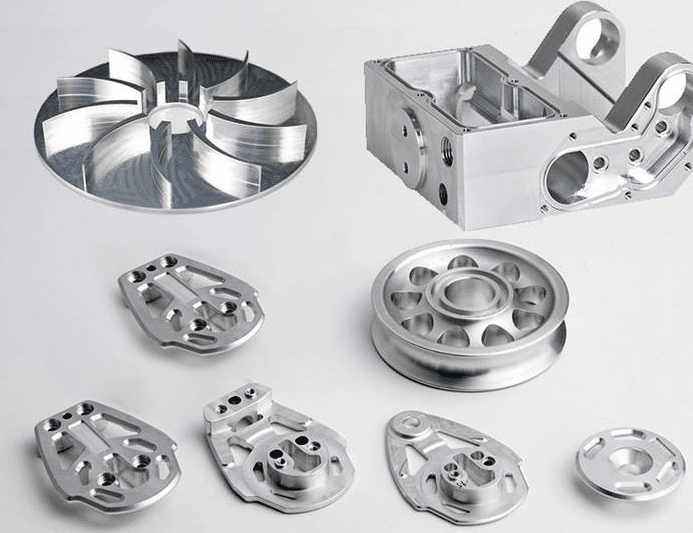

Anxin offers services for both metal and non-metal parts from prototypes to on-demand production. You can receive immediate quotations and choose from over 40 materials and more than 10 surface treatments. Upgrade your operations with the precision and efficiency of our CNC machining services.

Our factory is equipped with 3, 4 and 5-axis compound CNC machining centers with quickly changeable tooling to ensure reliable and rapid production. We also offer advanced features, including stricter tolerances, cost-saving pricing, and customized performance components according to your requirements.

1. High Precision, Good Consistency

One of the most significant advantages of CNC machining in our factory compared to manual machining is precision. Without the constant attention of a skilled operator, once programmed, CNC machines are able to maintain a high degree of consistent part quality in mass production.

2. Efficiency And Productivity

One of the advantages of CNC machining at ANXIN is that it is faster. In the use of CNC machine tools, because CNC machine tools can be mass-produced 24 hours without fatigue, the operator can be more efficient

3. Flexibility And Adaptability

The CNC machining in ANXIN’s factory can complete any mechanical part you can think of, just be able to give the product drawings, they are different from the traditional machine production process, because the CNC machine can be programmed to adapt to different design requirements or production tasks, so its products are very adaptable

4. More Detailed Processing

The CNC machining at the ANXIN’s plant can achieve very fine tolerances and is suitable for high-precision engineering requirements. It can also be machined to a smooth surface, reducing the need for subsequent finishing.

AT offers a wide variety of materials for custom CNC machining, plastic, and metal, including but not limited to:

Aluminum: 6061-T6, 7075-T6, 2024, 5052, 6060, 5083, 2017, 6082

Aluminum’s strength-to-weight ratio, affordability, and recyclability have made it widely used across industries worldwide.

Stainless Steel/Alloy Steel/Tool Steel/Brass/Copper/Titanium

Finishing Options: Anodizing Types II, III, III + PTFE, ENP, Media Blasting, Nickel Plating, Powder Coating, Tumble Polishing

POM(Delrin/Acetal): High stiffness, good moisture resistance, high wear-resistance, and low friction, easy to machine

PMMA (Acrylic):Color:(White, black, brown)

PEEK: Grade: POM-C, POM-H, UV stabilized POM, Food-Grade POM

ABS/Nylon (PA)/PTFE (Teflon)/PVC