Die casting is an efficient metal casting process in which molten metals (such as aluminum, zinc, magnesium alloy) are injected into precision steel molds at high speed and cooled in a short time.

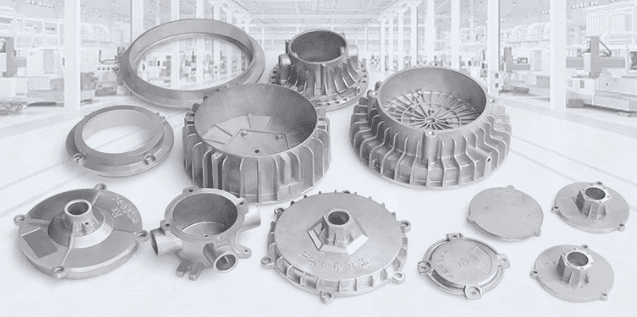

ANXIN is a recognized leader in providing sophisticated forming dies to make high-quality finished metal parts. More than just a service provider, we’re dedicated to being your true product development partner. We provide threaded holes, machined faces, o-ring grooves, undercuts and other complex features. All raw materials used in our die casting service, for tooling as well as finished parts, are verified with positive material identification using advanced scientific measuring and test equipment.

Die casting involves the injection of molten metal, under enormous pressure, into the hollow cavity of a custom-made steel forming die. It’s the fastest and most cost-effective way to produce medium to high volumes of metal parts with excellent surface finish and dimensional accuracy.

A. Factories that mass-produce castings in large quantities should create conditions to adopt technologically advanced molding and core-making methods.

B. Castings produced in small batches of one piece – heavy castings produced in small batches of one piece. Hand shaping is still an important method. Manual modeling can adapt to various complex requirements and is more flexible, and does not require a lot of process equipment.

C. Special casting low pressure casting, die casting, centrifugal casting and other casting methods. Due to the high price of equipment and molds, it is only suitable for mass production.

We provide high pressure die casting in several different alloys of aluminum, zinc, and magnesium. Your choice of materials may depend on cost, weight and performance. Here are some tips: